Explore all custom shoulder / neck rigid boxes

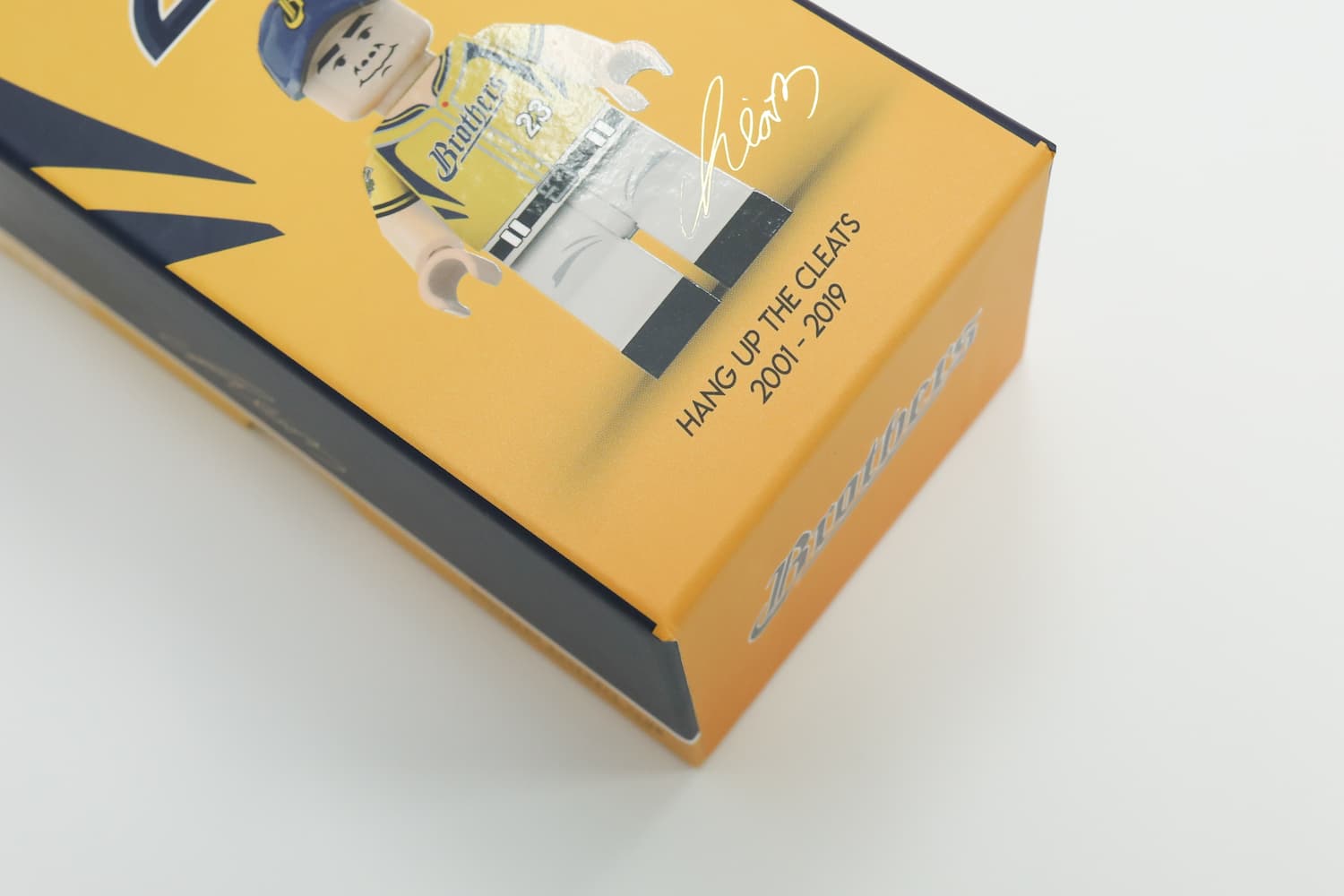

Speak volumes with this sophisticated custom box solution. This style is very popular, able to withstand the jostling of being carried around while looking untouched. It’s often friction-locked to secure the contents within. Customize it however you like! Added a matte finish, embossing, even EVA foam inserts to create a high-end appeal.

Options & Materials

Our curated list of materials and finishes available to everyone

Pantone Metallic

Standardized metallic color system for extreme color accuracy when printing.

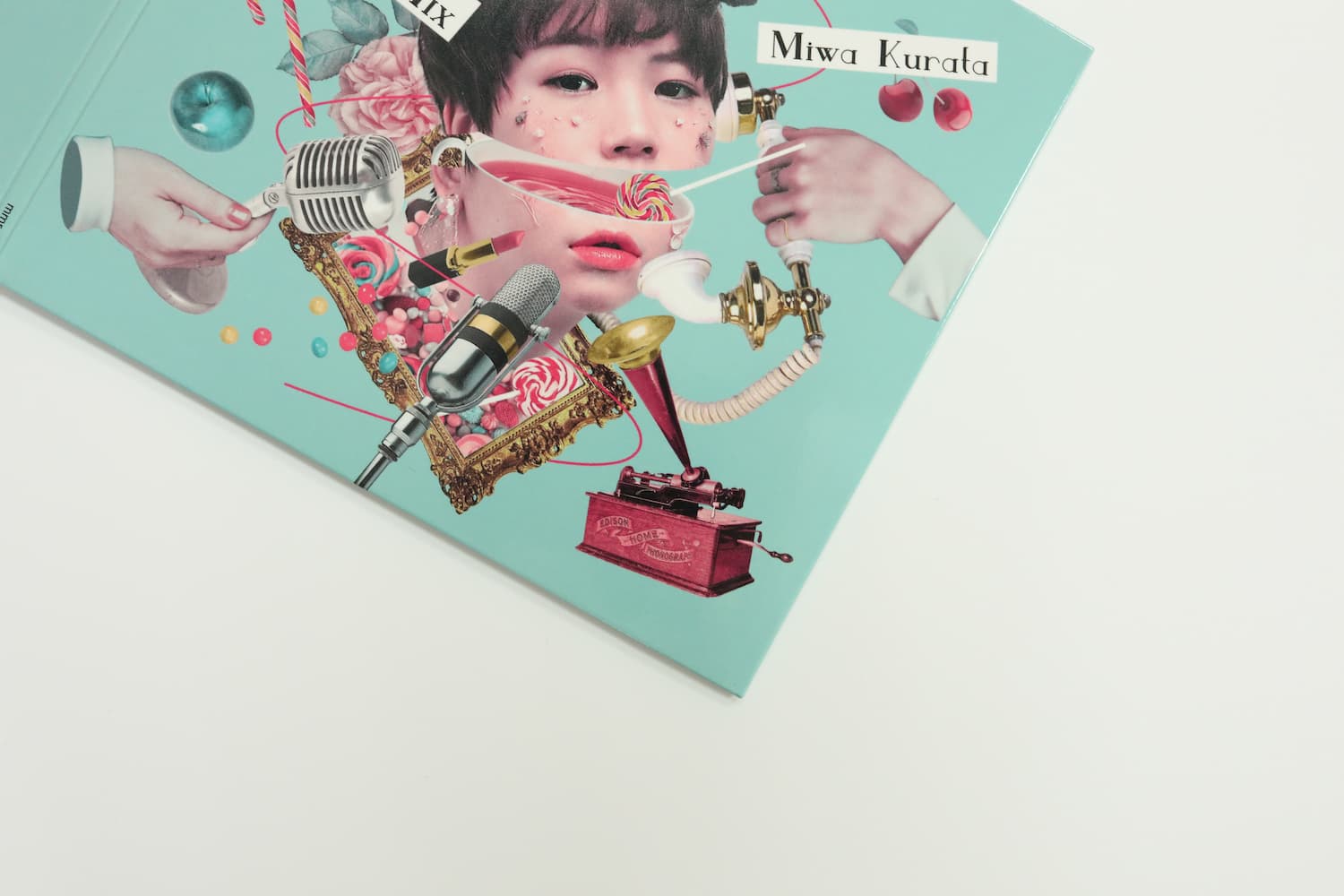

Digital Print

Low volume printing option with relatively low set-up costs.

Window Patching

Special technique with a transparent plastic film covering the cut-out.

Window Cut-Out

Special process where a cut-out is created on the packaging surface.

Embossing / Debossing

Special process that creates a raised or recessed pattern on the surface.

Food Grade Coating

Ink coating that protects the interior of the box for food-safe applications.

Satin Varnish

Inexpensive option that coats and adds surface protection.

AQ Coating

Water-based coating that creates a soft semi-gloss surface.

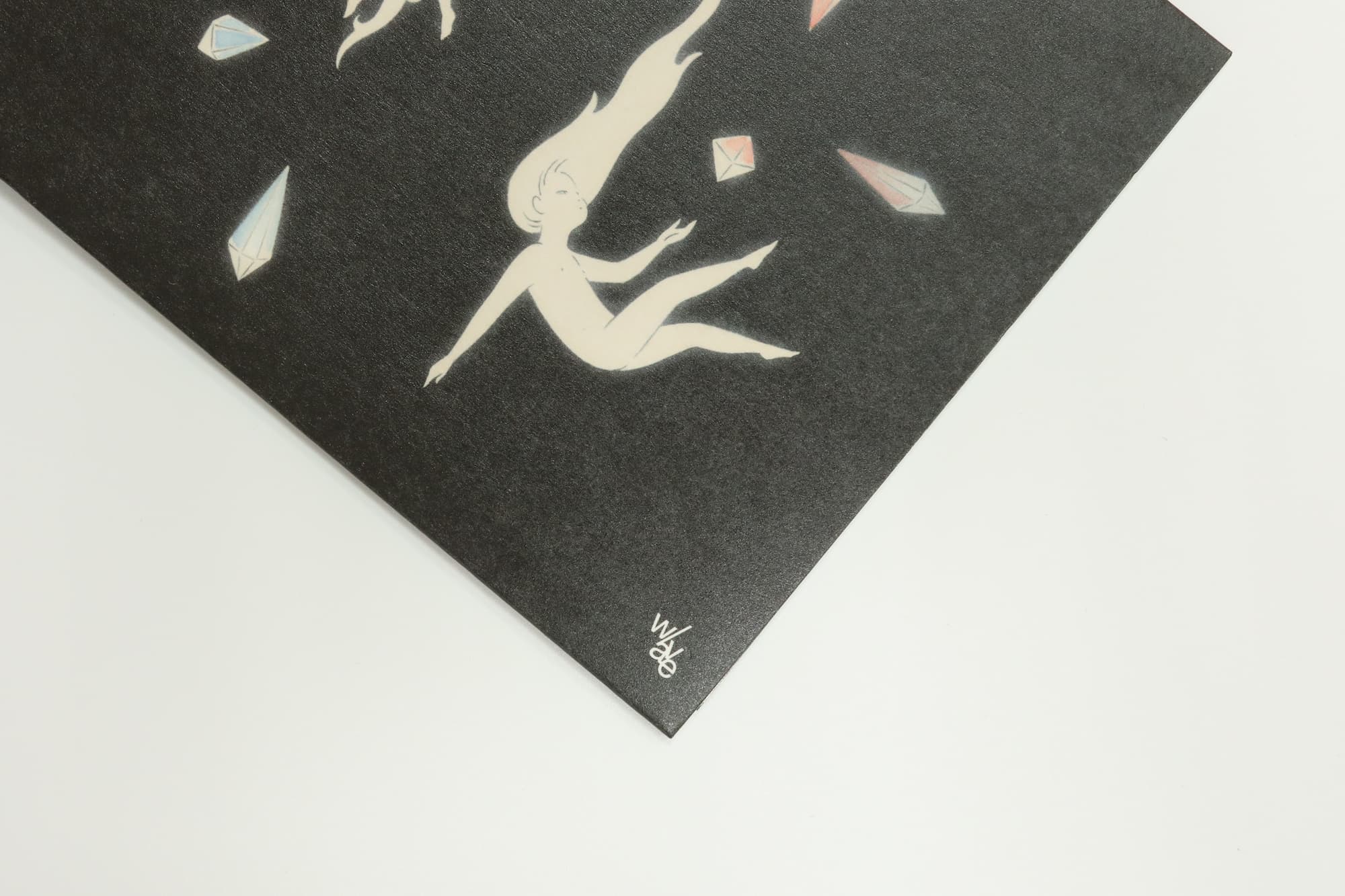

Matte Lamination

Thin plastic film that gives the box surface a matte surface.

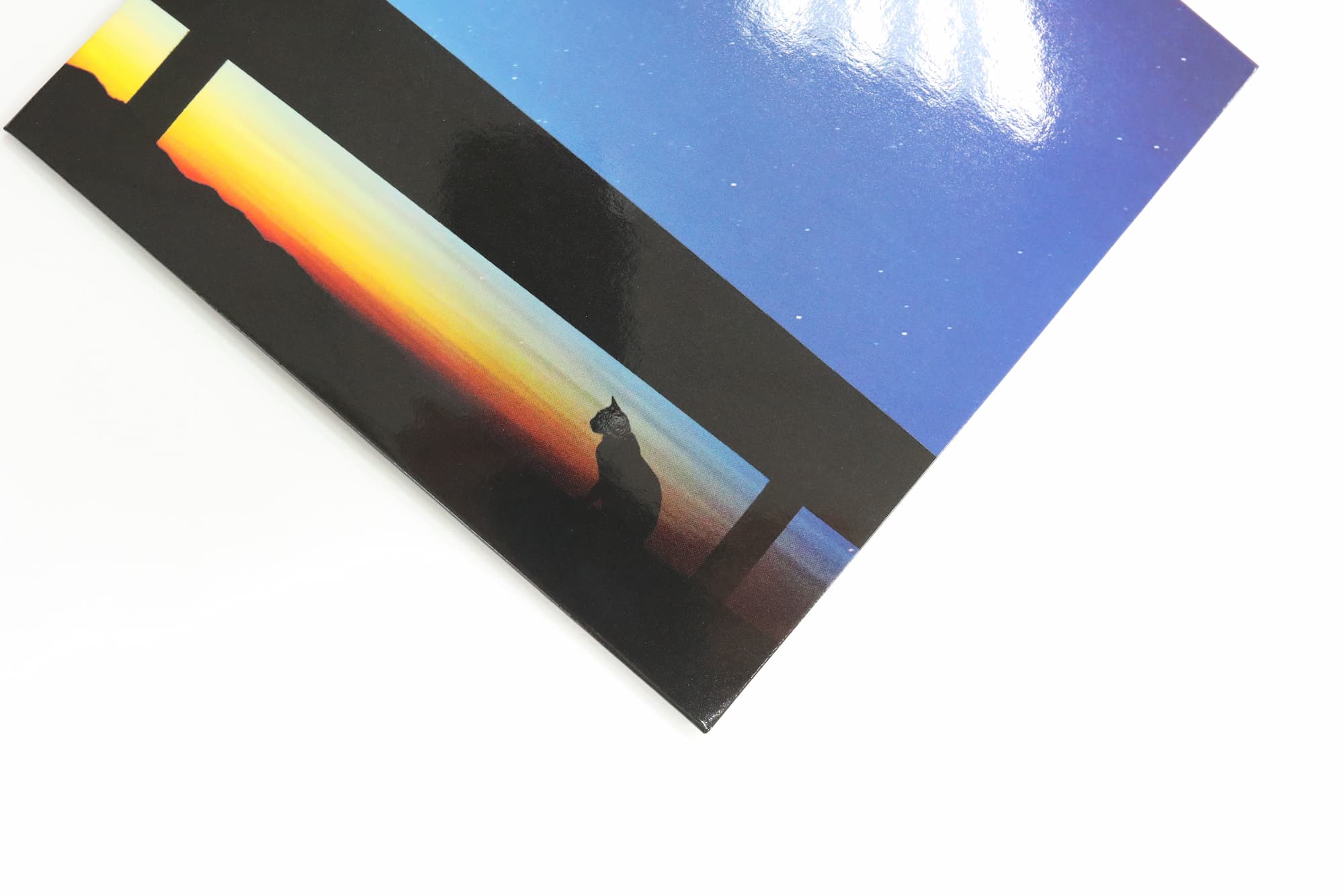

Gloss Lamination

Thin plastic film that gives the box surface a glossy surface.

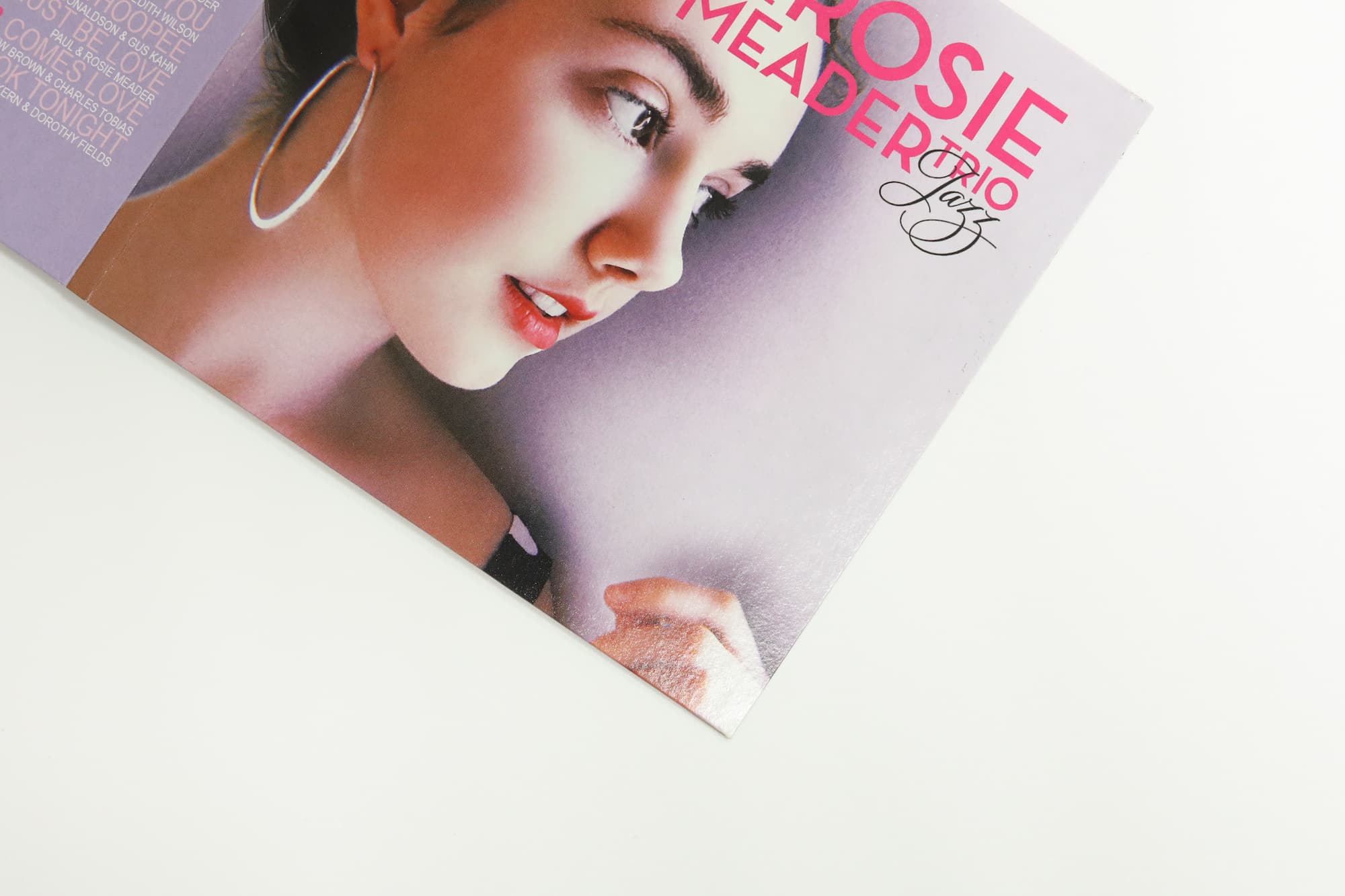

Offset / Lithography

Ideal for printing in finer details with access to more options and finishes.

Unlimited Capabilities

Give a sneak peek of your products with window patching! Window patching is a great way to create anticipation and excitement because it gives the customer a small glimpsed of what to expect in your packaging.

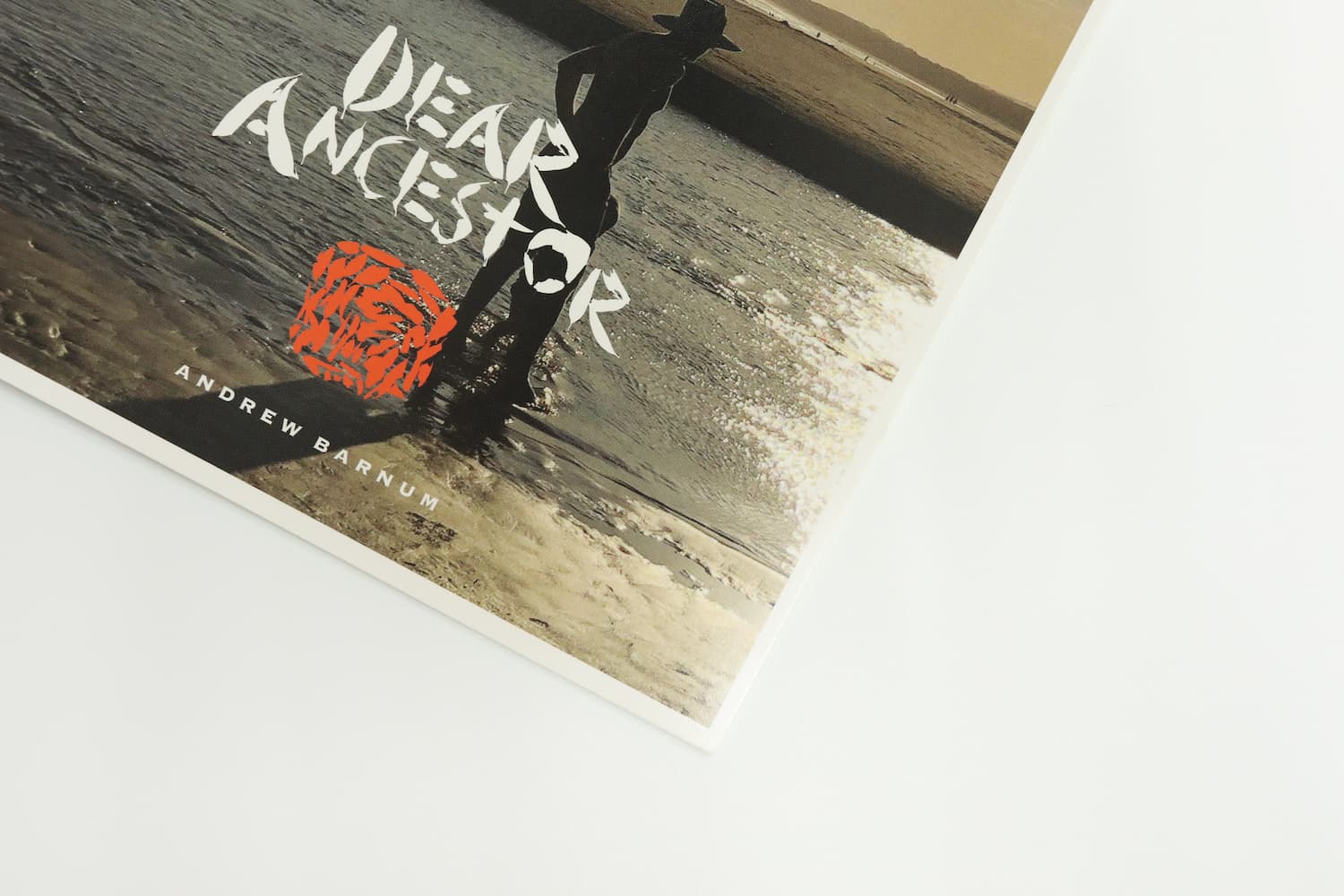

High-End Appeal

The neck component of the packaging creates interest and personality.

Strong Structural Design

Made with high-quality chipboard for strength and security.